Form Diameter Spline - One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition fit; Form diameter is that diameter. Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. For example, iso h7 (the outside diameter of the.

For example, iso h7 (the outside diameter of the. One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition fit; Form diameter is that diameter. Diametral pitch (p) is the number of spline teeth per inch of pitch diameter.

One of the most frequently neglected areas of gear design is the determination of form diameter': Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. Form diameter is that diameter. The tolerance of the major diameter of the internal spline should be selected as a transition fit; For example, iso h7 (the outside diameter of the.

Different centralized spline fittings (a) minor diameter fit, (b

Form diameter is that diameter. The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. One of the most frequently neglected areas of gear design is the determination of form diameter': For example, iso h7 (the outside diameter of.

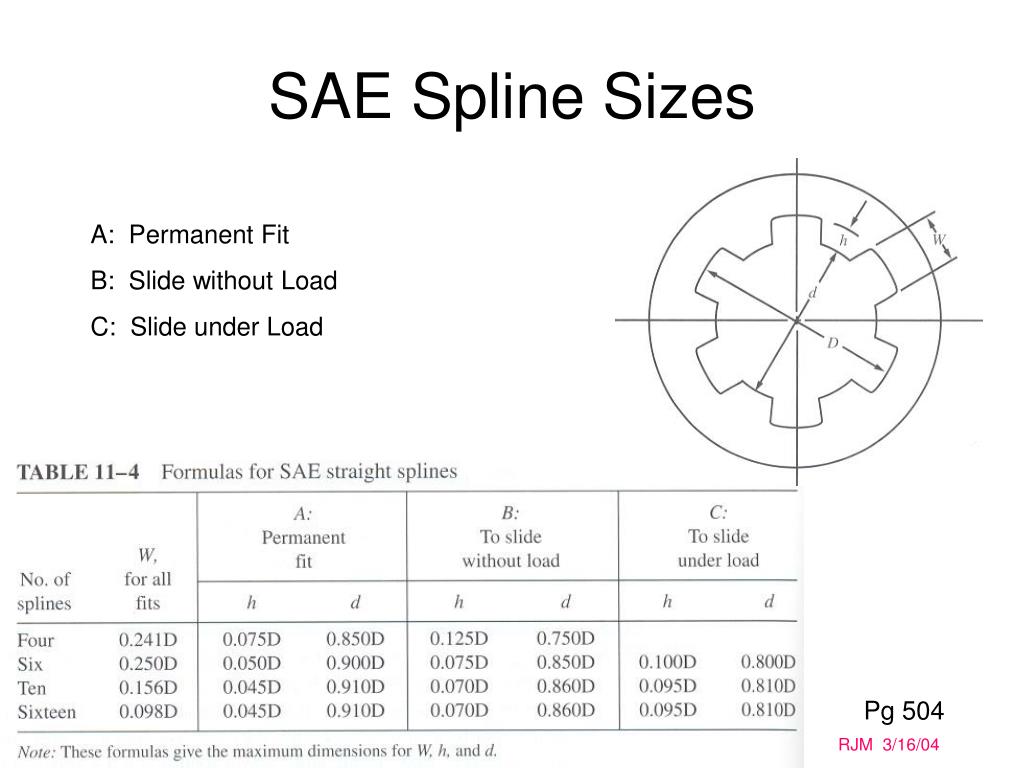

Shaft Spline Dimensions Chart

Form diameter is that diameter. One of the most frequently neglected areas of gear design is the determination of form diameter': For example, iso h7 (the outside diameter of the. The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch.

Spline Design Photos All

The tolerance of the major diameter of the internal spline should be selected as a transition fit; Form diameter is that diameter. For example, iso h7 (the outside diameter of the. One of the most frequently neglected areas of gear design is the determination of form diameter': Diametral pitch (p) is the number of spline teeth per inch of pitch.

mechanical engineering Flat root spline vs filet root spline what's

Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. Form diameter is that diameter. For example, iso h7 (the outside diameter of the. The tolerance of the major diameter of the internal spline should be selected as a transition fit; One of the most frequently neglected areas of gear design is the determination of form.

Sae Spline Size Chart

For example, iso h7 (the outside diameter of the. One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. Form diameter is that.

Free Online Area Spline Graph Maker

Form diameter is that diameter. For example, iso h7 (the outside diameter of the. Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition.

Spline Shaft Tables

For example, iso h7 (the outside diameter of the. Form diameter is that diameter. One of the most frequently neglected areas of gear design is the determination of form diameter': Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. The tolerance of the major diameter of the internal spline should be selected as a transition.

spline Word of the Day English The Free Dictionary Language Forums

For example, iso h7 (the outside diameter of the. One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. Form diameter is that.

Spline Gauges Kanak Machine Tools

Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. The tolerance of the major diameter of the internal spline should be selected as a transition fit; One of the most frequently neglected areas of gear design is the determination of form diameter': Form diameter is that diameter. For example, iso h7 (the outside diameter of.

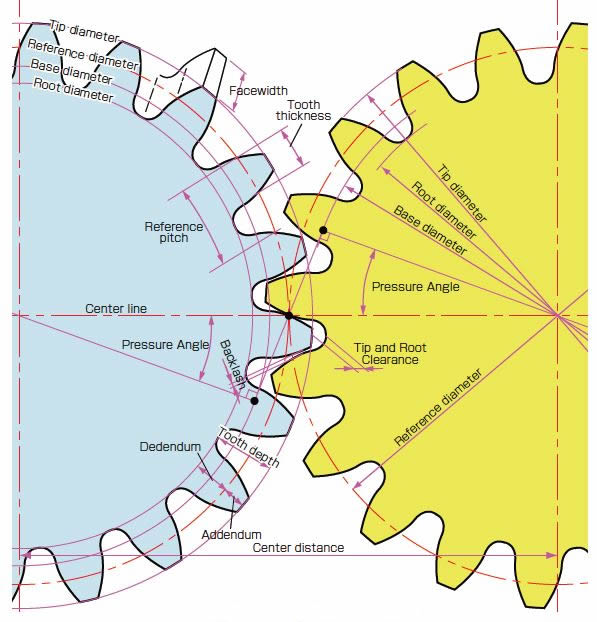

Pitch Circle Diameter GearWords KHK Gears

Form diameter is that diameter. One of the most frequently neglected areas of gear design is the determination of form diameter': The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. For example, iso h7 (the outside diameter of.

One Of The Most Frequently Neglected Areas Of Gear Design Is The Determination Of Form Diameter':

The tolerance of the major diameter of the internal spline should be selected as a transition fit; Diametral pitch (p) is the number of spline teeth per inch of pitch diameter. Form diameter is that diameter. For example, iso h7 (the outside diameter of the.