Sheet Metal Fab - View a comprehensive table of. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Force is applied between a punch (upper tool) and die (bottom. Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine. Cutouts, holes) proximity to bends;. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3d visualized design for manufacturability (dfm) feedback to help. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our manufacturing analysis can improve the quality of sheet metal parts by:

Cutouts, holes) proximity to bends;. We offer 3d visualized design for manufacturability (dfm) feedback to help. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our manufacturing analysis can improve the quality of sheet metal parts by: Force is applied between a punch (upper tool) and die (bottom. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine. View a comprehensive table of.

View a comprehensive table of. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Cutouts, holes) proximity to bends;. Our manufacturing analysis can improve the quality of sheet metal parts by: Force is applied between a punch (upper tool) and die (bottom. Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine. We offer 3d visualized design for manufacturability (dfm) feedback to help.

Sheet Metal Fabrication Transforming Metal into Precise Creations

Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. We offer 3d visualized design for manufacturability (dfm) feedback to help. Cutouts, holes) proximity to bends;. View a comprehensive table of. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in.

What Is The Sheet Metal Fabrication Process? Estes Design & Manufacturing

Our manufacturing analysis can improve the quality of sheet metal parts by: Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake.

Catalog Coil Metal Fabrication Customer Sheet Metal Projects

View a comprehensive table of. Our manufacturing analysis can improve the quality of sheet metal parts by: Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days..

A List of Common Sheet Metal Fabrication Techniques KP FABRICATION

Our manufacturing analysis can improve the quality of sheet metal parts by: We offer 3d visualized design for manufacturability (dfm) feedback to help. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024.

CostEffective Precision Sheet Metal Fabrication Process

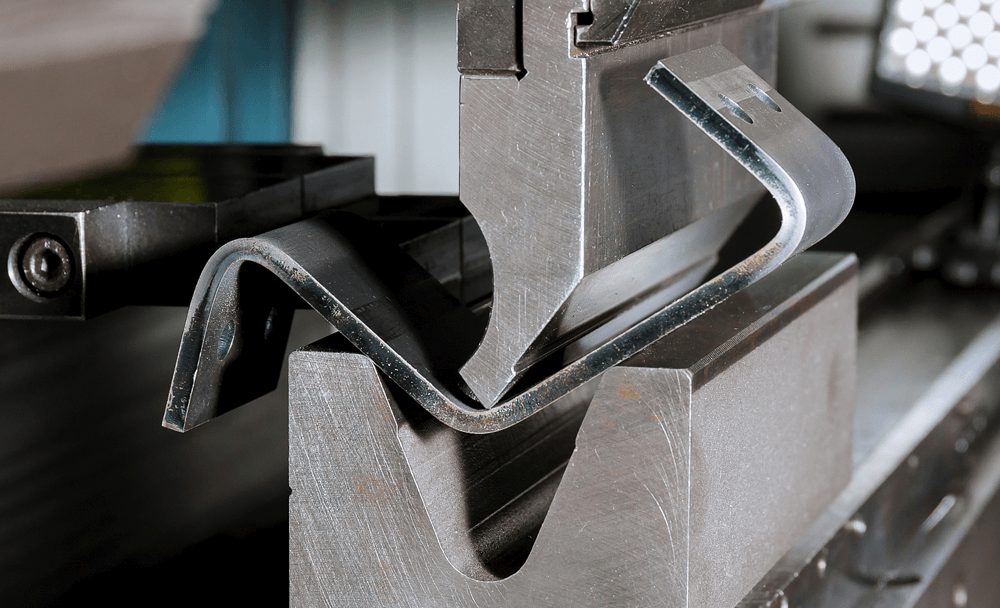

Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine. We offer 3d visualized design for manufacturability (dfm) feedback to help. Force is applied between a punch (upper tool) and die (bottom. Our manufacturing analysis can improve the quality of sheet metal parts by: Our online sheet metal.

Sheet Metal Fabrication 101 everything you need to know

Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Force is applied between a punch (upper tool) and die (bottom. Cutouts, holes) proximity to bends;. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Our.

4 Tips of Sheet Metal Fabrication Proto Expedited

Cutouts, holes) proximity to bends;. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses.

Sheet Metal Fabrication

We offer 3d visualized design for manufacturability (dfm) feedback to help. Cutouts, holes) proximity to bends;. View a comprehensive table of. Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine.

Sheet Metal Fabrication An Ultimate Guide on Manufacturing Processes

Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Force is applied between a punch (upper tool) and die (bottom. Our manufacturing analysis can improve the quality of sheet metal parts by: Press brake forming is a metal fabrication process that bends flat sheet metal into.

Sheet Metal Fabrication

Cutouts, holes) proximity to bends;. Our online sheet metal fabrication service enables you get a quote in minutes and have your parts delivered in days. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Force is applied between a punch (upper tool) and die (bottom. Press.

We Offer 3D Visualized Design For Manufacturability (Dfm) Feedback To Help.

Cutouts, holes) proximity to bends;. Press brake forming is a metal fabrication process that bends flat sheet metal into a final shape using a press brake machine. Force is applied between a punch (upper tool) and die (bottom. View a comprehensive table of.

Our Online Sheet Metal Fabrication Service Enables You Get A Quote In Minutes And Have Your Parts Delivered In Days.

Our sheet metal fabrication service stocks industry standard sheet metal material thicknesses from 0.024 in. Sheet metal fabrication combines several manufacturing technologies such as laser cutting, press brake forming, and welding to achieve a variety of custom designs. Our manufacturing analysis can improve the quality of sheet metal parts by: