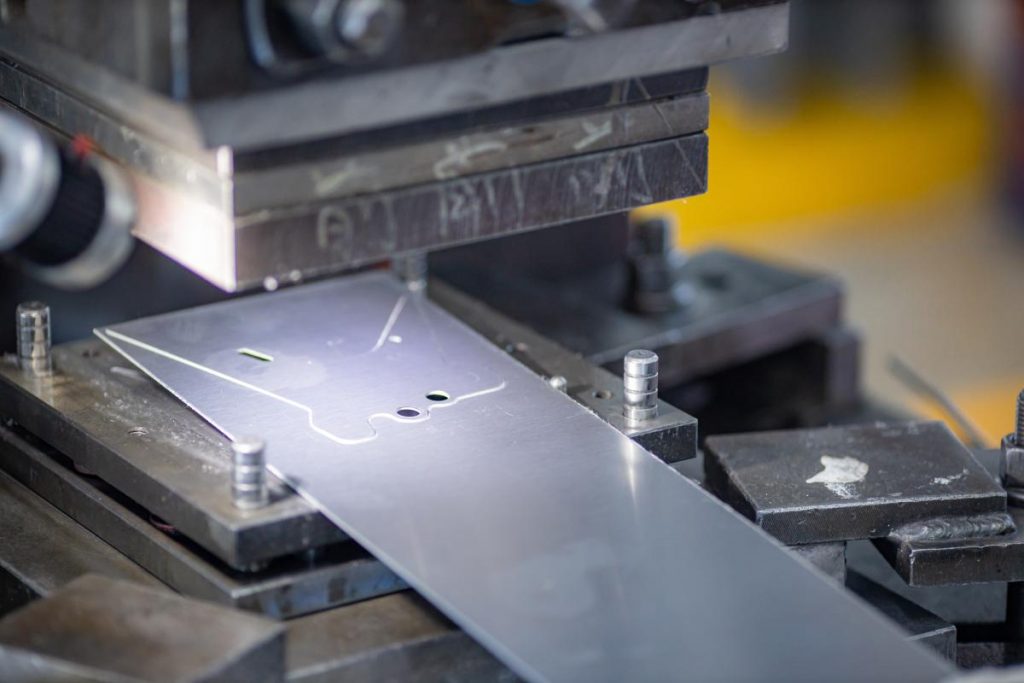

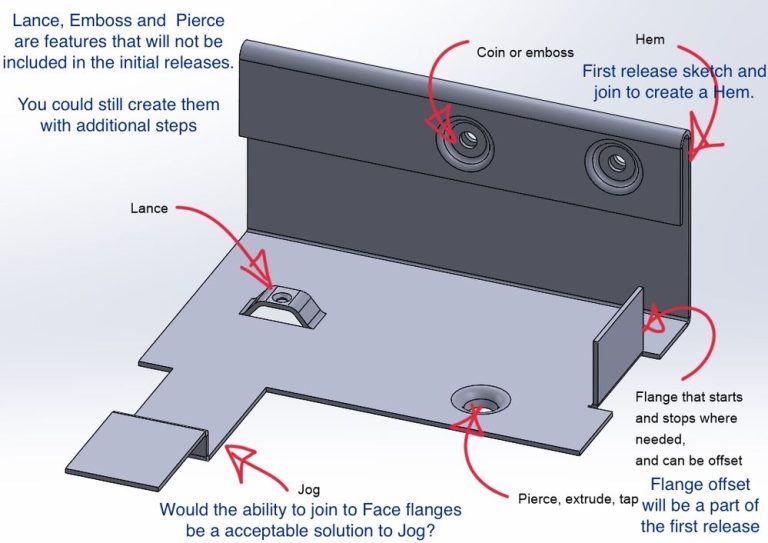

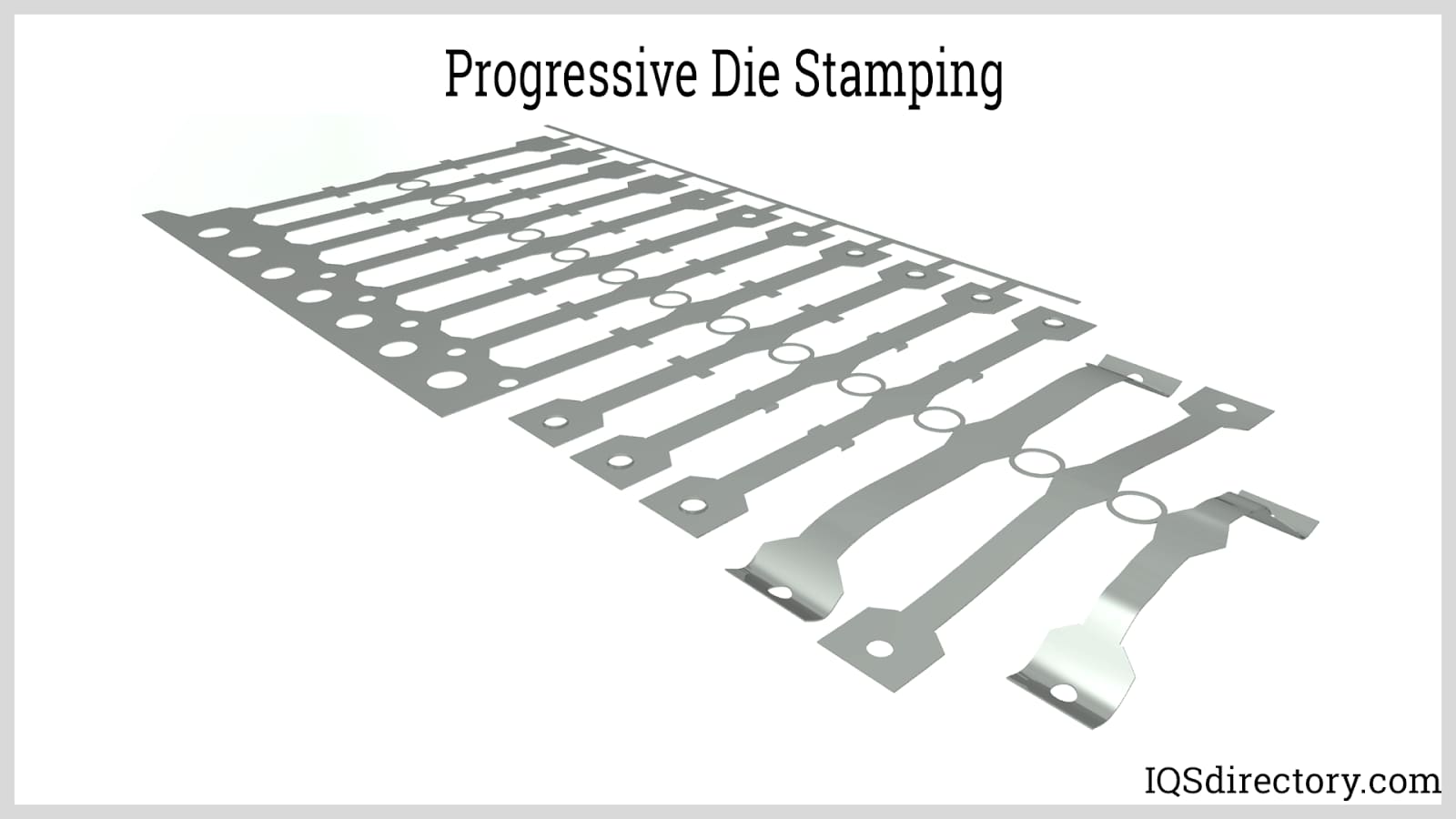

Stamp Sheet Metal - The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. In this process, a flat sheet of metal,. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images.

Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. In this process, a flat sheet of metal,. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components.

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. In this process, a flat sheet of metal,. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components.

Proses Stamping dalam Pengolahan Sheet Metal KMI

The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. In this process, a flat sheet of metal,. Sheet metal stamping plays a.

Precision Metal Stamping and How We Do It Metalcraft

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. In this process, a flat sheet of metal,. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Sheet metal stamping plays a.

The Perks of Sheet Metal Stamping Schwab Industries Schwab Industries

In this process, a flat sheet of metal,. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Our primer.

UNDERSTANDING SHEET METAL STAMPING GUIDELINE FOR BUYERS AM

In this process, a flat sheet of metal,. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The.

30. STAMPING ( ALL TYPE ) IN SHEET METAL IN CATIA V5. YouTube

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Our primer about sheet metal stamping covers the basics including.

Sheet Metal Stamping Process Aranda Tooling

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. Our primer about sheet metal stamping covers the basics including.

The Basics of Sheet Metal Stamping

Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Sheet metal stamping plays a.

Understanding The Basics Of The Metal Press Stamping Process

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. Our primer.

Sheet Metal Stamping Process Step by Step YouTube

In this process, a flat sheet of metal,. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. Stamping or.

Sheet Metal Stamping Dies & Processes at Bernice Barry blog

Stamping or pressing is a manufacturing process used to convert flat metal sheets into final shapes. In this process, a flat sheet of metal,. Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. Sheet metal stamping plays a.

Stamping Or Pressing Is A Manufacturing Process Used To Convert Flat Metal Sheets Into Final Shapes.

Our primer about sheet metal stamping covers the basics including the materials, equipment, and view images. Sheet metal stamping plays a vital role in metal manufacturing, offering efficient ways to shape and form metal components. The steps of the sheet metal stamping process include blanking, piercing, bending, drawing, and flanging. In this process, a flat sheet of metal,.